Did you know outdated pigging systems could be costing your plant thousands each year in waste, inefficiencies, and compliance risks?

In the fast-paced world of manufacturing, staying ahead of the curve is crucial. As industries evolve, so do the technologies that support them.

If your plant is still relying on outdated pigging systems, you could be missing out on significant opportunities to enhance safety, productivity, and efficiency.

Why Pigging Systems Are Essential in Process Industries

Liquid Product Recovery (Pigging) systems have long been an essential part of industries like food and beverage, paint, personal care, confectionery and many other liquid manufacturing processes. They recover valuable product from pipelines at the end of the transfer process.

However, as production demands grow and sustainability becomes more of a priority, the limitations of older pigging technology can hinder your plant’s performance.

In this post, we’ll explore why it’s time to consider upgrading to a modern, high-tech pigging solution from HPS Product Recovery Solutions, and how this investment can significantly enhance your operations.

Safety: Modern Pigging Solutions Minimise Risk

Outdated pigging systems often come with outdated safety protocols. As production lines become more complex, the need for reliable safety features increases.

Older systems often rely on manual operations creating a higher risk of human error, contamination, and failures.

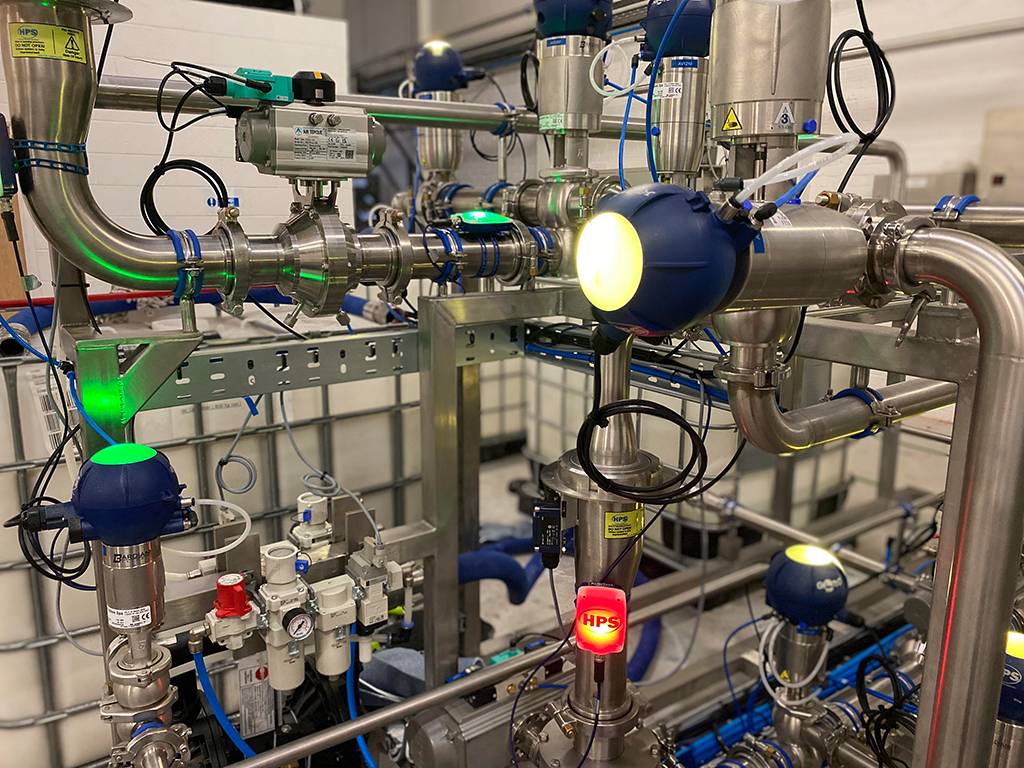

HPS Advanced Pigging Solutions are designed with cutting-edge safety features that reduce these risks. Our modern systems incorporate:

- Full Automation: Minimises manual intervention by utilising closed-loop automatic pigging systems, ensuring a safer and more efficient process, with minimal chance of operator error.

- Real-Time Monitoring: Key pigging system components such as specialist valves are equipped with IO-link technology for real-time monitoring. This ensures optimal system performance and enables faster troubleshooting when needed.

- Advanced Alerts: The Pig Health Software offers clear alerts when the pig used in your system approaches its recommended usage limits, ensuring proactive maintenance.

- State-of-the-Art Pig Detection: Provides accurate and continuous presence monitoring for PLC systems and automation software, eliminating false signals.

- Comprehensive Safety Features: Includes physical barriers, venting, automatic decompression, and more to enhance operational safety

By upgrading to a modern HPS pigging system, you’re not just improving operational efficiency; you’re safeguarding your employees, your equipment, the environment, and the integrity of your product.

Productivity: Efficiency Gains with Modern Technology

Outdated pigging systems can cause delays, inefficiencies, and increased downtime.

Whether it’s because the old system isn’t able to handle the demands of a higher throughput or requires frequent maintenance, these inefficiencies can add up quickly and impact your bottom line.

HPS Advanced Pigging Solutions are engineered for optimal performance in high-demand environments:

- Faster Product Recovery: Modern systems can recover more product with less waste, ensuring you maximise raw material usage and minimise product losses.

- Reduced Downtime: With fewer maintenance needs and faster pigging cycles, you can reduce downtime, keeping your production lines running smoothly and efficiently.

- Flexible Integration: HPS pigging systems can be easily integrated into existing pipelines, eliminating the hassle of a complete system overhaul.

By upgrading to a more efficient pigging solution, you can streamline operations, increase throughput, and boost overall productivity.

Efficiency: Maximise Resources and Minimise Waste

One of the most significant advantages of modern pigging technology is its ability to reduce waste and optimise resource usage.

Outdated systems might not be as effective in removing every last bit of product from the pipeline, leading to higher waste and the need for more water or cleaning agents.

HPS Pigging Systems are designed with efficiency in mind:

- Minimal Waste: HPS systems use advanced technology to recover up to 99.5% of product from full pipelines, reducing waste and improving yield.

- Water and Chemical Savings: Dual-pig pigging systems, for example, offer more efficient cleaning capabilities, significantly reducing the amount of water and chemicals required for each cleaning cycle. This not only saves money but also helps ensure compliance with environmental regulations.

- Sustainability: By reducing waste and conserving resources, you contribute to a more sustainable operation, helping your plant achieve its environmental goals.

In today’s competitive market, reducing operational costs and improving resource efficiency are essential. HPS pigging systems help you meet both of these objectives, while also improving your plant’s overall environmental footprint.

Cost Savings: Get More Out of Your Investment

While choosing a modern pigging system may seem like a significant upfront investment, it’s important to consider the long-term savings.

Outdated systems often result in higher maintenance costs, more frequent replacements, and greater inefficiencies that can eat into your profits.

With HPS Pigging Technology, your investment will pay off in:

- Lower Maintenance Costs: Modern systems are built to last longer and require less maintenance, reducing both the frequency and cost of repairs.

- Increased Product Recovery: More efficient product recovery means you’re getting more out of every batch, leading to fewer losses and a better pig system ROI.

- Operational Cost Reduction: With improved efficiency, you’ll use fewer resources like water, cleaning agents, and energy, resulting in significant operational cost savings.

The HPS Advantage: Why Choose Us?

Upgrading to a modern pigging system doesn’t just mean better performance—it means partnering with a company that understands the unique needs of your industry and provides solutions that are reliable, scalable, and tailored to your operations.

Why choose HPS?

- Proven Track Record: With years of experience in product recovery solutions, HPS has helped countless clients optimise their production lines.

- Customisable Solutions: We offer tailored pigging systems that meet the specific needs of your plant, whether it’s for food and beverage, paint, lubricants, chemicals, personal care products, or other industries.

- Ongoing Support: From implementation to after-sales service, HPS provides full support to ensure your pigging systems perform at their best.

Make the Upgrade Today!

If your facility is still relying on outdated pigging technology, the time to upgrade is now. HPS Advanced Pigging Solutions offer superior safety, productivity, efficiency, and cost savings that will help your plant remain competitive in an ever-evolving market.

Don’t let outdated technology hold you back. Talk to HPS today about our latest technology, and start realising the benefits of a modern, efficient, and sustainable pigging system.